PRODUCTS

Product Details

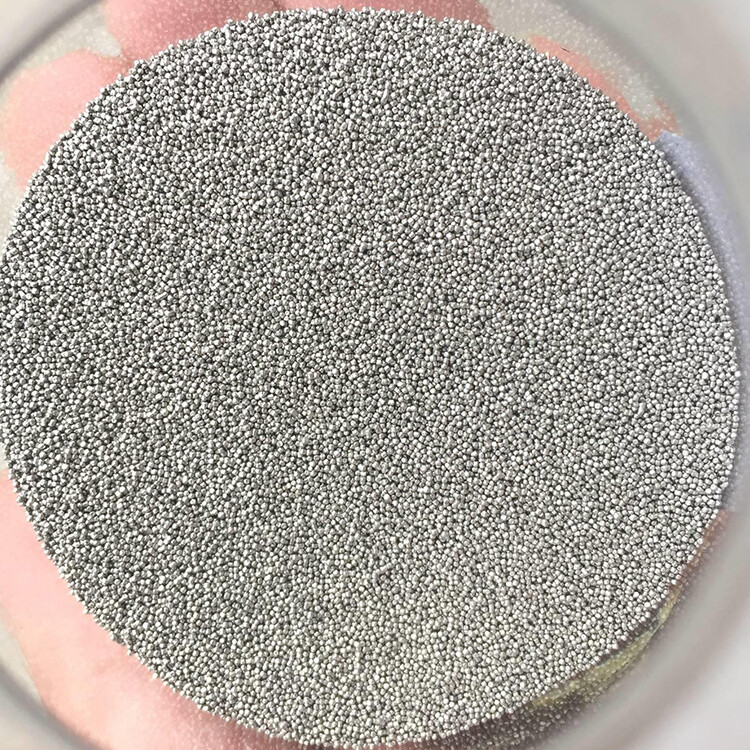

Cast steel shot is made of high-quality steel scraps, and is made into small spherical steel shots through processes such as melting, high-pressure water jet molding, and heat treatment. Cast steel shot has good wear resistance, impact resistance, and corrosion resistance, and is widely used in metal surface treatment, shot peening, casting cleaning, pipeline descaling, and other fields.

Manufacturing process

The production process of cast steel shot includes the following main steps:

Melting: Melt high-quality steel scraps.

Molding: Molten steel is formed into small balls by high-pressure water jet.

Heat treatment: Heat again to purify the homogeneity, and then quench.

Tempering: The quenched steel shot is dried in the furnace and reheated and tempered to achieve the appropriate hardness.

Grading: The tempered steel shot is sorted into 11 grades that meet SAE standards through a mechanical screen.

Application areas

Cast steel shot is widely used in the following fields:

Before painting steel workpieces: Used for descaling and rust removal, usually using centrifugal shot blasting equipment.

Foundry Industry: Used to remove sand from the surface of workpieces. Aviation, Automobile, Sandblasting/Painting: Surface treatment and strengthening. Oil and Gas Pipelines: Pipeline descaling. Performance Characteristics Cast steel shot has the following performance characteristics: Abrasion resistance: Ability to maintain its shape and hardness for a long time. Impact resistance: Ability to remain intact under high-speed impact. Corrosion resistance: Ability to remain stable in harsh environments. Controllable hardness: Its hardness can be adjusted through tempering to meet the needs of different applications.

Message

RELATED PRODUCTS