PRODUCTS

Product Details

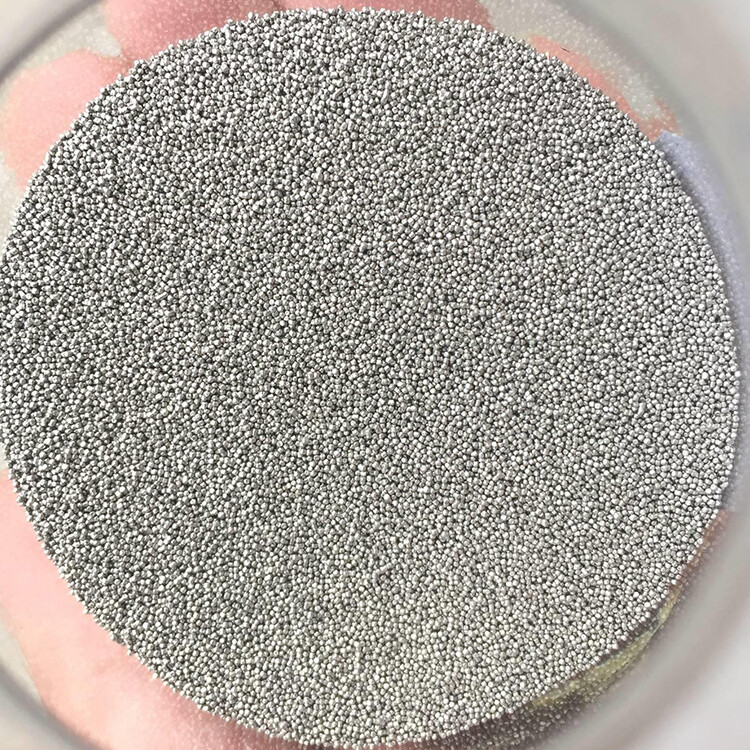

Brown corundum is made of bauxite and coke (anthracite) as the main raw materials, and is smelted at high temperature in an electric arc furnace. The grinding tools made of it are suitable for grinding metals with high tensile strength, such as various general steels, forgeable cast iron, hard bronze, etc., and can also be used to manufacture high-grade refractory materials. Brown corundum has the characteristics of high purity, good crystallization, strong fluidity, low linear expansion coefficient, and corrosion resistance. It has been verified by dozens of refractory manufacturers that this product has the characteristics of no explosion, no pulverization, and no cracking during the application process. In particular, its cost-effectiveness is much higher than that of traditional brown corundum, making it the best aggregate and filler for brown corundum refractory materials.

Message

RELATED PRODUCTS