PRODUCTS

Product Details

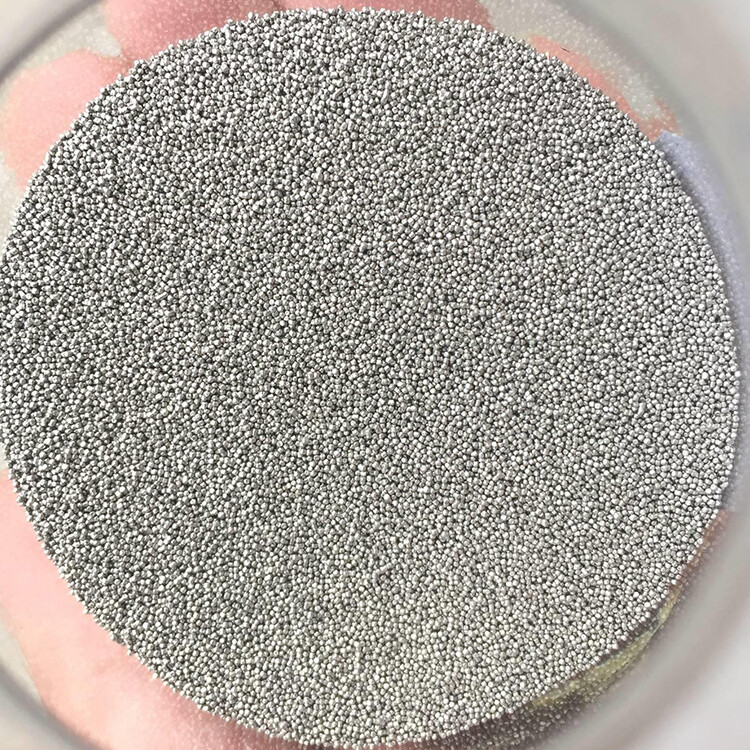

It is mainly made of a- Al2O3 alumina, kaolin and plastic refractory clay as the main raw materials, with feldspar, quartz and binder added, etc., and is made through careful batching, ball milling, screening, iron removal, vacuum mud making, molding, drying and high-temperature sintering. Through strict process control and quality monitoring of raw materials, mud, semi-finished products and finished products, the product has a smooth surface and dense porcelain after sintering. There is no sandwich and stratification inside. Inert porcelain balls have good mechanical strength, wear resistance, handling resistance, and strong impact resistance. It also has excellent high temperature resistance, thermal shock resistance, and corrosion resistance (except hydrofluoric acid, it can resist the corrosion of all inorganic acids and organic acids and various organic solvents). Therefore, it has the advantages of long service life. Inert porcelain balls can be widely used in special occasions with conditions of 300℃~1500℃, high pressure, high corrosion and high impact.

Message

RELATED PRODUCTS